【Product description】: GGBS (Slag product applications) vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBFS) into small particles.GGBS (fineness:4200-4500cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing, for which the percentage of GGBS usage is typically at 10-15% and 20-25% respectively.

【Product capacity】: 200,000-1,500,000t/a

【Specific surface area】: 420~450 m²/kg

1. Reduce investment costs, intelligent control

2. Adjust fineness according to demands

3. Power consumption per set of GRMS is not more than 30Kwh

4. Remarkable energy-saving and environmental protection, convenient maintenance

5. Original spare parts to reduce maintenance worries

6. Metal recovery rate of per-ton slag is great

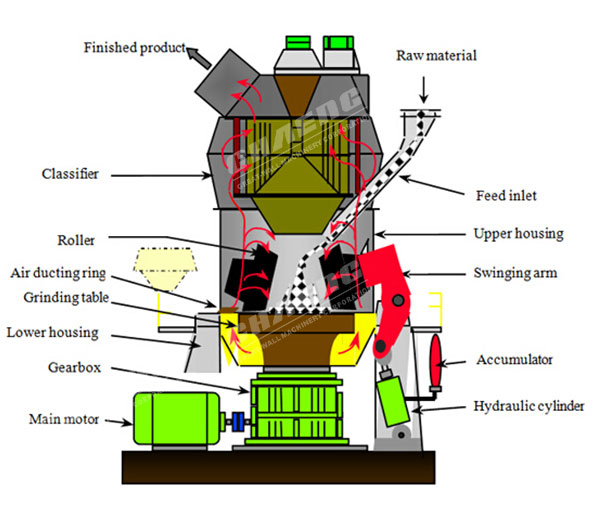

The material through the feed tube fell into the center of grinding plate, and then the materials outwards the surrounding area of grinding plate at centrifugal force, to forms a certain thick layer of materials bed, at the same time material was crushed by number of vertical mill rollers. The materials continuous moving to the outer edge of the grinding plate, off the grinding plate materials rising with the hot air which enter from wind ring into the vertical roller mill, through the vertical roller mill shell into the middle of the separator, in this course materials and hot gas got a fully heat exchange, the water quickly evaporates. Separator controls the finished product output size, greater than the specified size are separated and fall back to the plate, while meet the fineness demands are brought through the separator into the finished product warehouse.

| Model | Grinding Table Diameter (mm) | Motor (kW) | Output (t/h) |

|---|---|---|---|

| GRMS19 | 1900 | 560 | 15 |

| GRMS23 | 2300 | 710 | 20 |

| GRMS26 | 2600 | 1000 | 28 |

| GRMS30 | 3000 | 1400 | 40 |

| GRMS33 | 3300 | 1600 | 45 |

| GRMS36 | 3600 | 2000 | 60 |

| GRMS38 | 3800 | 2240 | 65 |

| GRMS40 | 4000 | 2500 | 75 |

| GRMS43 | 4300 | 3000 | 90 |

| GRMS46 | 4600 | 3150 | 95 |

| GRMS50 | 5000 | 4000 | 125 |

| GRMS53 | 5300 | 4500 | 145 |

| GRMS56 | 5600 | 5000 | 155 |

| GRMS60 | 6000 | 6300 | 180 |

| GRMS65 | 6500 | 7300 | 220 |

| GRMS70 | 7000 | 8500 | 260 |

Project name: Great Wall machinery slag powder demonstration and training base with annual production of 600,000t

Project address: Great Wall Road, Mengzhuang Town, Huixian City, Henan Province

Contracting mode: General contracting---turnkey project

Host configuration: GRMS 46.41 slag vertical roller mill

Production capacity: Annual production of 600,000t slag powder

Project company: Tangshan Hongyan building material Co., Ltd

Project address: Accumulation Area, Coastal Industry, Leting County, Bohai Bay.

Contracting mode: General contracting---turnkey project

Host configuration: GRMS 46.41,GRMS33.31 slag vertical roller mill

Production capacity: Annual production of 900,000t slag powder

E-mail: [email protected]

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China