【Product Description】: CHAENG can undertake the 100-1500t/d active lime production line EPC, including the reach report, civil engineering, designing, equipment, installation and debugging.

【Raw material】: limestone

【Capacity】: 100-1500t/d

【Equipment configuration】: lime rotary kiln + vertical preheater + vertical cooler

1. High activity, and good quality: the activity of the finished product can reach 360ml, underfiring and overburning rate <8%,and the quality is uniform.

2. Advanced technology, energy conservation and environment protection: advanced calcination technology, low energy consumption; temperature of discharged fuel gas < 220℃, which is good for dust collection, and can fully meet the requirements of energy conservation and environment protection;

3. Large output. The maximum capacity for a single line can be 1000 t/d.

4. High degree of automation, and easy operation. Adopt DCS remote control system with high degree of automation.

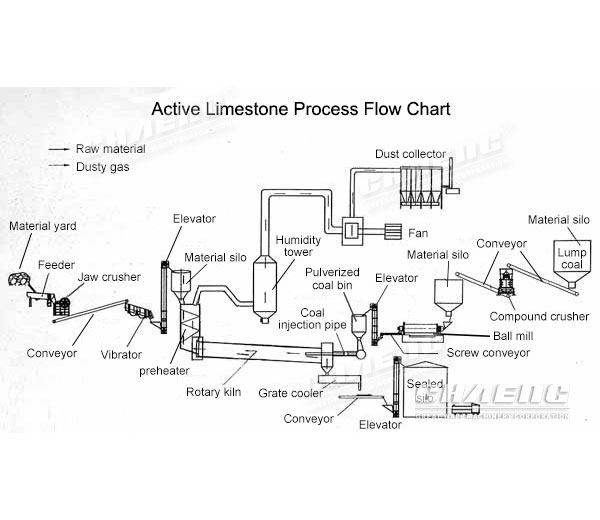

Qualified limestone (20 ~ 50 mm) are lifted by bucket elevator to top silo of preheater. There are two level indicators (up and down) controlling the feeding amount, then they are separated averagely into preheaters’ individual rooms. The limestone’s temperature rises to about 900℃ heated by kiln flue gas of 1150℃, about 30% of them are decomposed, and they come into the rotary kiln by hydraulic rod, where the limestone decomposed into CaO and CO2. The decomposed limestone are put into the cooler, where its temperatures drops to 100℃ and released. The hot air (600°C) will come to kiln after heat exchange, and mix with coal gas for mixture combustion. The exhaust gas is released by the blower into bag deduster through multi-pipe cooler, then into the chimney though exhaust blower.The limestone from the cooler will be transported to the limestone final product silo through vibrating feeder, chain conveyer, bucket elevator, belt conveyer.

| Designed capacity (T/D) | 200 | 300 | 400 | 600 | 800 | 1000 | |

|---|---|---|---|---|---|---|---|

| Product | active lime | active lime | active lime | active lime | active lime | active lime | |

| Preheater | specifications | RS-6.5×3.4 | RS-7.5×3.4 | RS-8.5×3.4 | RS-10.×3.4 | RS-10.8×3.4 | RS-13.5×3.4 |

| Number of push rod | 6 | 8 | 10 | 12 | 16 | 18 | |

| Kiln | specifications | φ2.8×42M | φ3.3×50M | φ3.6×56M | φ4×60M | φ4.3×66M | φ4.8×68M |

| Effective volume (m³) | 190 | 292 | 430 | 575 | 738 | 1005 | |

| speed (r/min) | 0.45-2.22 | 0.2-1.9 | 0.22-1.57 | 0.48-1.57 | 0.21-1.57 | 0.19-1.98 | |

| Cooler | specifications | LS-3×3 | LS-3.6×3.6 | LS-3.8×3.8 | LS-4.1×4.1 | LS-4.7×4.7 | LS-5.2×5.2 |

| Feed temperature | 1100±50℃ | 1100±50℃ | 1100±50℃ | 1100±50℃ | 1100±50℃ | 1100±50℃ | |

| Discharge temperature | <100℃ | <100℃ | <100℃ | <100℃ | <100℃ | <100℃ | |

| Weight(T) | 35 | 40 | 50 | ||||

| Heat rate (KJ/Kg) | 5200 | 5200 | 5100 | 5000 | 5000 | 5000 | |

| Activity (50g,4NHCL,10MIN) | ≥360ML | ≥360ML | ≥360ML | ≥360ML | ≥360ML | ≥360ML | |

In 2014 , a building material factory from guangxi province of China purchased a lime production line with annual output of 400,000 tons. The main equipment includes φ4.0×60m rotary kiln, φ2.4×4.75m coal mill, 5000 m² bag type dust collector. And all of these equipment were made by CHAENG independently, and CHAENG provided installation and commissioning guidance.

E-mail: info@chaeng.co

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China