【Application】: Cement Plant Thermal Power Plant

【Output】: 300-3000 t/d

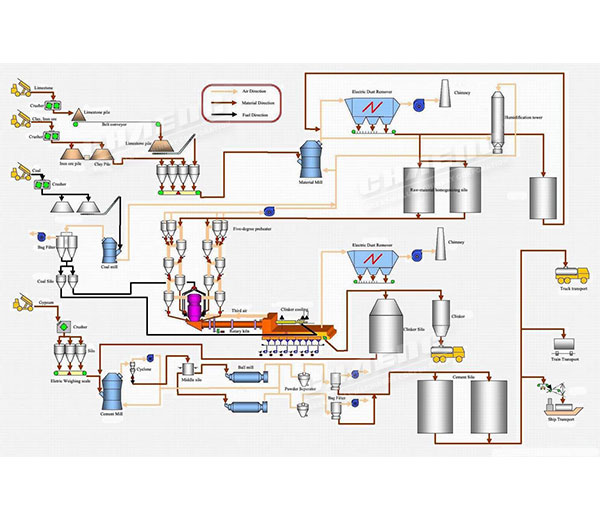

【Process Type】: New Dry Process

【Blaine Fineness】: 3300-3800 cm²/g

1.Timely And Fast Delivery

Chaeng Machinery is equipped with large steel foundry and machining workshop, which ensure the fast and high-quality production of the related equipment of cement production line. Besides, the goods are delivered in time, reducing time costs of customers.

2. Excellent Service

The company provides all-round service to customers, including project design, operation training, roller surfacing, millstone maintenance, technical support and so on, making customers use our products safely and produce efficiently.

3. Mature General Contracting Project

The company has a domestic first-rate technical team, and cooperates with domestic chief vertical roller mill experts. The company can design detailed general contracting project according to the actual situation of customers, and provide one-stop turnkey service from building projects to production and operation.

4. Advanced Dry Process Cement Production Technology

The cement production line launched by the company adopts the well-received new dry process cement preparation technology, which reduces heat consumption effectively, reducing production costs and improving the benefit.

first, crushing and pre-homogenization. Crushing is required for most raw materials such as limestone, clay, iron ore and coal. The crushed raw materials use scientific stacking and reclaiming technology to achieve the initial homogenization of raw materials to facilitate subsequent grinding. Second, the preparation of cement raw meal. The homogenized raw materials are ground by a raw meal vertical mill to obtain the particle size required for the production of cement clinker. Third, clinker production. The ground raw meal is homogenized. After the treatment, under the action of the preheater system, the raw meal exchanges heat with the high-temperature air, thereby promoting the further decomposition of the raw material in the rotary kiln to form cement clinker. Fourth, cement clinker grinding. Cement grinding is the final process of cement manufacturing, using a cement mill to grind the cement clinker to suitable particle size. Fifth, cement packaging and delivery. Cement delivery can be divided into bags or bulk delivery, CHAENG has cement bag packing machines and bulk machines to choose from.

| CHAENG provide capacity of 5500t/d cement production line configuration table | |||

|---|---|---|---|

| System | Raw material grinding | Coal grinding | Cement grinding |

| Specification | GRMR53.41 3800kW | GRMC36.4 1250kW | GRMK46.41 4550kW |

| Separator | 200kW | 132kW | 315kW |

| Fan | 900000m3/h 11500Pa 4000kW | 245000m3/h 9900Pa 1000kW | 50000m3/h 8000Pa 1600kW |

| Capacity and Fineness | ≥430 t/h R80um=12% | 45 t/h R80um=3% | 150 t/h 3300cm2/g |

| Feeding | 95% < 80mm | 95% < 50mm | 95% < 40mm |

Uzbekistan customer officially signed a cement production line of 1000TPD with CHAENG on March 16, 2016. From the customer inspection to the final cooperation, it took less than 10 days, because CHAENG's strong strength and 60 years’ experience, which make customers so trust.

E-mail: info@chaeng.co

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China