【Materials】: Steel slag

【Main equipment】: GRMSS Steel Slag Vertical Mill

【Applications】: Roads, building materials, soil amendments, sewage treatment

1. Independent patent, reliable performance

It has its own patented technology in iron removal before grinding, during grinding and after grinding. Through the internal iron removal, external circulation iron removal, high-pressure and less-roller grinding technologies, the metal iron in industrial solid waste can be effectively removed.

2. Finished product with good economic benefits

GRM series vertical roller mill of CHAENG adopts unique roller sleeve and lining plate. The finished product has high fineness, specific surface area of more than 450-500 m2/kg, and good activity. It is suitable for cement active mixture, concrete admixture and cementitious material.

3. Advanced technology, better energy saving effect

Using the vertical grinding process, the energy consumption of the system is reduced to below 40kW·h/t, which is 20% less than the conventional process. At the same time, the entire production line adopts DCS central control system, which has a high degree of automation and is easy to operate.

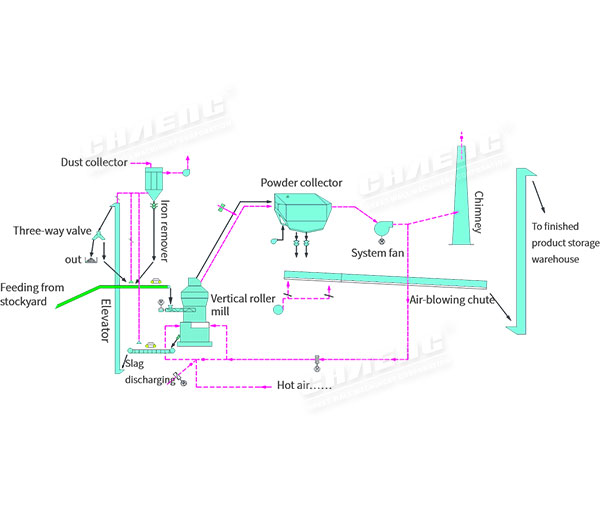

The steel slag produced by steelmaking process in the steel plants is contained in slag pots and is dumped into the drum/hot stuffy tank. The steel slag is pretreated by drum / hot disintegrating method to separate iron content, and stimulate the stability and activity. After the pretreated steel slag is screened by the vibrating feed screen to remove large pieces of steel slag, it enters the crushing and magnetic separation system which crushes the steel slag by a rod mill. The pretreated steel slag with particle size ≤5mm and metal iron content ≤2% will be sent to the GRMSS series steel slag vertical mill developed by CHAENG for final grinding. With the help of the hot air provided by the hot blast stove, the pulverized materials are selected by the powder separator and dried at the same time. The finished products that meet the requirements are finally transported to the dust collector, and then entered into the finished product warehouse by the air transport chute and elevator.

| Items | 600,000t/a slag grinding plant Energy consumption | 450,000t/a slag grinding plant Energy consumption | 300,000t/a slag grinding plant Energy consumption |

|---|---|---|---|

| Output(t/h) | 105 | 65 | 50 |

| Annual output (×10,000 tons) | 60 | 45 | 30 |

| Total Power(KW) | 5400 | 3770 | 2860 |

| The power at 10KV(KW) | 4400 | 3140 | 2230 |

| Transformer specifications | 1000KVA | 630KVA | 630KVA |

| Power consumption /unit product (Kwh/ton) | 40 | 40~41 | 42 |

| Coal consumption /unit product (kg/ton) | 18 | 18 | 18 |

The slag produced by blast furnace smelting in iron and steel plants has large amount, many types and is difficult to treat. In order to fully turn blast furnace slag into treasure, Jinxi Steel Group New Materials Company has invested in two slag powder production lines with an annual output of 1.8 million tons, processing more than 3 million tons of industrial solid waste such as slag and steel slag every year. Steel slag is sent to the vertical roller mill grinding system after hot disintegration, magnetic separation, crushing, and screening, and finally forms cementitious material as the basic material of the building materials industry.

E-mail: info@chaeng.co

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China