【Application Industry】: Cement Plant

【Output】:21~210 t/h

【Effective Volume】: 29.5~185 m3

【Power Consumption】: 17~22kWh/t

1. less investment and quick benefit

2. special streamline design

3. more effective structural design

4. free and flexible working manner

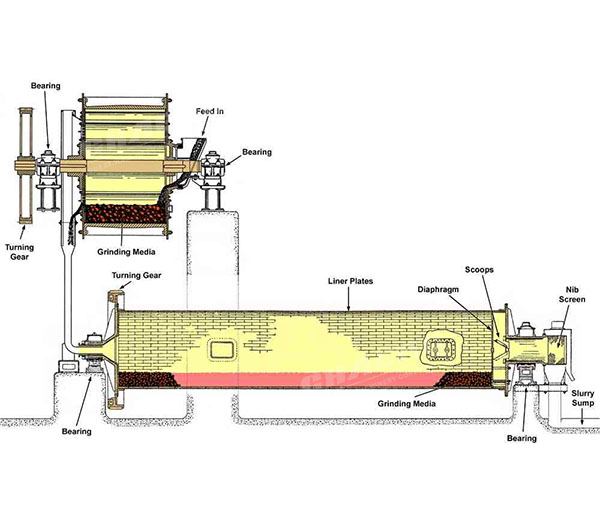

The raw material mill usually adopts two ways: edge drive and center drive. The materials enter the mill continuously and evenly through the feeder, and the motor drives the cylinder to rotate via the reducer. Firstly, the materials enter the first cabin spirally through the hollow shaft. Due to the rotation of the cylinder, frictional force and centrifugal force generate between steel balls and materials and cylinder. Under the effect of centrifugal force, the materials are brought to a certain height, and the materials scatter and drop in a material curtain form, then struck and grinded by steel balls. The sorting equipment selects qualified materials from the grinded finished product, and in the circulation grinding system, the unqualified materials are sent back to the mill and struck and grinded by the grinding media until the fineness is qualified.

| Model | Output | Rotate speed | Feeding size | Grinding media load | Effective volume | Drive mode | Motor | Gearbox | Weight |

|---|---|---|---|---|---|---|---|---|---|

| m | t/h | r/min | mm | t | m³ | kW | t | ||

| Φ2.4×7.5 | 21-23 | 20.4 | ≤25 | 37.5 | 29.5 | edge | 475 | CZD80 | 76 |

| Φ2.4×10 | 30 | 20.4 | ≤25 | 50 | 39 | edge | 570 | MBY630 | 94 |

| Φ2.6×8 | 20-24 | 19.57 | ≤25 | 52 | 38.1 | edge | 630 | MBY630 | 97 |

| Φ2.6×9 (closed-circuit) | 42 | 19.57 | ≤25 | 58 | 42.7 | edge | 710 | MBY710 | 125 |

| Φ3.0×9 | 28-32 | 18.3 | ≤25 | 78 | 57.4 | edge | 1000 | MBY630 | 150 |

| Φ3.4×7.5 | 60 | 16.9 | ≤25 | 80 | 58 | edge | 1000 | MBY710 | 167 |

| Φ3.8×7.5 | 90 | 17 | ≤25 | 95 | 91.8 | edge | 1600 | JDX900 | 218 (excluding motor) |

| Φ4.0×9 | 120-140 | 16 | ≤25 | 140 | 106 | edge | 1800 | JDX1000 | 269 |

| Φ4.6×10+3.5 | 190 | 15 | ≤25 | 190 | 177 | center | 3550 | JS150-B | 352 (excluding driving parts) |

| Φ4.6×10.5+3.5 | 210 | 15 | ≤25 | 200 | 185 | center | 3550 | JS150-B | 358 (excluding driving parts) |

Project company: Chongqing Jinjiang Cement Co., LTD

Project address: Jinlong Science &Technology Industrial Zone, Tongliang County, Chongqing City

Main engine: Ball mill

Production capacity: 5000t/d cement grinding

E-mail: info@chaeng.co

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China