【Product description】: Rotary Lime kiln is the main equipment which is widely used for calcined active lime production.

【Product capacity】: 100-1500 t/d

【Motor Power】: 160-630 kW

【Product application】: Active lime production line, cement production line and calcium carbonate decomposition production line, etc.

1. Activity is higher than the traditional shaft kiln 30ml

2. Production capacity reaches up to 1500 t/d

3. Auto-control reduce the labor cost

4. Good quality of finished products, the probability of mild and excessive calcination less than 8%.

5. Gas fuel, energy saving and environmental protection

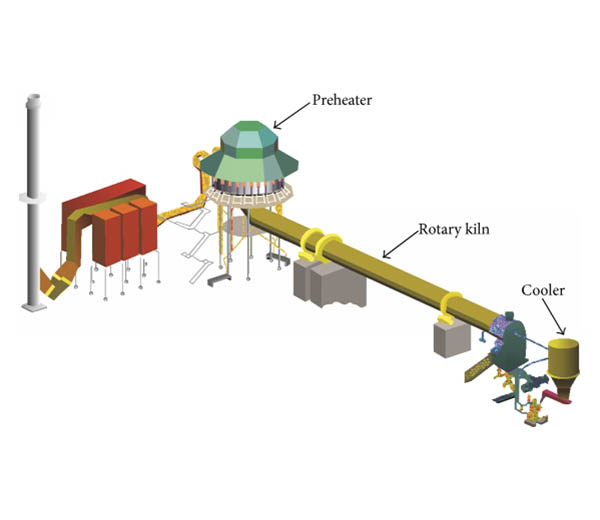

The lime rotary kiln process is the material will be fed into the kiln tail through the chute in the gas chamber. As the kiln shell is inclined and rotates slightly, material will move along the round shell and move along shaft direction from kiln tail to kiln head. The material will be processed through pre-heat, decompose, calcined and will be fed into a cooler. Fuel will be given through gas or coal burner at kiln head and will be combusted in the kiln. Heat will be transferred to material by fire radiate, hot air flow, kiln brick transfer. The heat will heat and calcine material enough and make its final product.

| Designed capacity (t/d) |

Product | Rotary kiln | ||

|---|---|---|---|---|

| Spec. (m) | Effective volume (m³) |

Burning temperature (℃) |

||

| 150 | active lime | Φ2.5×40 | 142 | 1350/1250 |

| 200 | active lime | Φ2.8×42 | 190 | 1350/1250 |

| 250 | active lime | Φ3×46 | 235 | 1350/1250 |

| 300 | active lime | Φ3.2×50 | 292 | 1350/1250 |

| 400 | active lime | Φ3.5×56 | 430 | 1350 |

| 500 | active lime | Φ3.8×58 | 505 | 1350 |

| 600 | active lime | Φ4×60 | 575 | 1350 |

| 800 | active lime | Φ4.3×64 | 738 | 1350 |

| 1000 | active lime | Φ4.8×68 | 1005 | 1350 |

In 2014, A company in Guangxi Province, China purchased a φ4.0 × 60m lime rotary kiln from CHAENG, the rotary kiln was installed in 2017, and it was put into use in June 2017. After use, customers made positive comments that machines of CHAENG have outstanding performance and are good at energy-saving to save large cost for users.

E-mail: [email protected]

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China