【Product description】: Coal ball mill is one of the auxiliary machine of the thermal power station and an important equipment for the pulverized coal preparation system.

【Product capacity】: 12-38 t/h

【Product application】: Power plants, cement plants, lime plants, etc.

【Power Consumption】: 23~33kWh/t

1. less investment, more energy-saving than similar products;

2. easy to operate, safe to use, stable and reliable performance;

3. running stably and continually, the production capacity is great

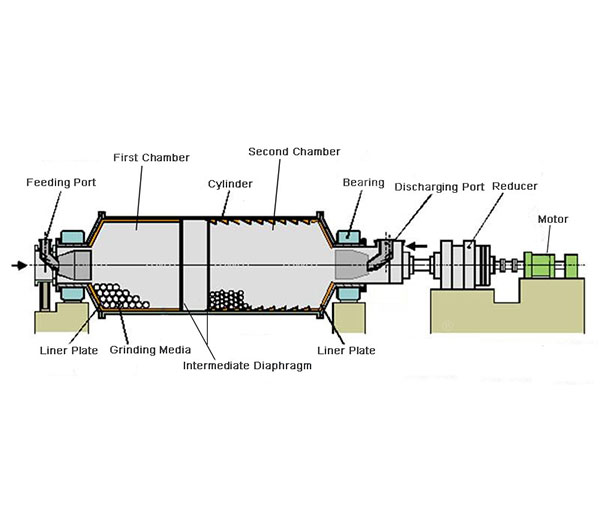

When working, the steel balls in the cylinder continuously hit and squeeze the coal to grind the coal into pulverized coal. The materials enter the first cabin of the mill spirally and evenly through the feeding apparatus and hollow shaft. In the first cabin, there is stepped liner or corrugated liner, and steel balls with different specifications. The centrifugal force generating from the rotation of the cylinder brings steel balls to a certain height, and then the balls fall, thumping and grinding the materials. After coarse grinding in the first cabin, the materials enter the second cabin by single-wall partition. There is flat liner and steel balls in the second cabin, where the materials are grinded further. Finally, the powder is discharged through discharge grate and the grinding operation is finished.

| Model | Output(t/h) | Rotate Speed(r/min) | Feed size(mm) | Effective Volume(m³) | Grinding Media Load(t) | Drive mode | Motor(KW) | Main reducer | Weight(t) |

|---|---|---|---|---|---|---|---|---|---|

| Φ2.4×4.75 | 12 | 20.4 | ≤25 | 19.3 | 22 | Rim drive | 280 | ZD60 | 50 |

| Φ2.4×4.5+2.0 | 12 | 20.4 | ≤25 | 18.3 | 22.6 | Rim drive | 280 | JD450 | 70.1 |

| Φ2.6×5.25+2.25 | 13-15 | 18.7 | ≤25 | 25.8 | 34 | Rim drive | 400 | MBY560 | 80 |

| Φ2.8×5.75+2.25 | 18-20 | 18.7 | ≤25 | 32.9 | 38 | Rim drive | 500 | MBY630 | 118.5 |

| Φ2.9×4.1 | 16 | 18.8 | ≤25 | 27.1 | 35 | Rim drive | 500 | JDX560 | 74 |

| Φ3.0×6.5+2.5 | 20 | 18.4 | ≤25 | 43.3 | 46.5 | Rim drive | 630 | JDX630 | 119 |

| Φ3.2×6.5+2.5 | 28 | 18 | ≤25 | 67 | 65 | Rim drive | 710 | JDX800 MBY800 |

153 |

| Φ3.4×6.0+3.0 | 30 | 17.47 | ≤25 | 64 | 60 | Rim drive | 900 | JDX800 | 167 |

| Φ3.4×7.5+1.5 | 30-38 | 17.5 | ≤25 | 64.1 | 70 | Rim drive | 1000 | MBY800 | 178 |

| Φ3.6×6.5+2.5 | 32 | 17 | ≤25 | 69 | 60 | Rim drive | 1000 | MBY800 | 204 |

| Φ3.8×7.0+2.5 | 38 | 16.4 | ≤25 | 75 | 80 | Rim drive | 1250 | JDX800 | 216 |

Φ3.2×13m three-bin high fine ball mill and coal mill are used in 1200t/d cement clinker production line in Xinjiang, China, and play extremely good production performance.

E-mail: info@chaeng.co

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China