【Product description】: Cement ball mill is mainly used in the grinding of finished products and raw materials in cement plants.

【Product capacity】:21-155 t/h

【Motor Power】: 800-3550 kw

【Specific surface area】:330-380m²/kg

1. advanced technology and good continuous behavior in service

2. The finished product has high fineness and large specific surface

3. high efficiency and large output

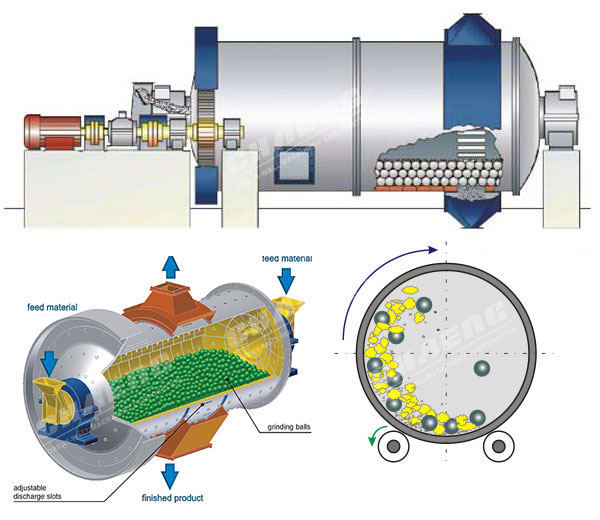

The cement mill is composed of horizontal cylinder, hollow shaft and other parts. The cylinder is long round barrel, and there are grinding media in it. The cylinder is made of steel plate, and there is steel liner fixed on the cylinder. The grinding media are usually steel balls, which are placed in the cylinder according to different diameters and certain proportion. The grinding media can also be steel forgings. When the cylinder rotates, due to the centrifugal force, the materials and grinding balls press close to the liner; due to the frictional force, the cylinder send the materials and grinding balls to a certain height; and then due to the gravity, the materials and grinding balls fall simultaneously and the grinding balls crush the materials. Meanwhile, sliding friction generating between the materials and liner grinds the materials, achieving the purpose of grinding the materials.

| Model | Output(t/h) | Rotate Speed(r/min) | Feed size(mm) | Grinding Media Load(t) | Effective Volume(m³) | Drive mode | Motor(KW) | Main reducer | Weight(t) |

|---|---|---|---|---|---|---|---|---|---|

| φ2.4*13 | 21-23 | 20.3 | ≤25 | 65 | 51.7 | Rim drive | 800 | JDX710 | 116 |

| φ2.6*13 | 28-32 | 19.61 | ≤25 | 75 | 60 | Rim drive | 1000 | JDX800 | 149 |

| φ3.0*13 | 33-37 | 18.08 | ≤25 | 108 | 80.9 | Rim drive | 1400 | JDX900 | 172.3 |

| φ3.2*13 | 45-50 | 18.04 | ≤25 | 128 | 92.4 | Rim drive | 1600 | MBY1000 JDX1000 |

218 |

| φ3.2*14 | 48-52 | 18.04 | ≤25 | 138 | 99.8 | Rim drive | 1800 | MBY1000 | 228 |

| φ3.4*11 | 45-50 | 18 | ≤25 | 115 | 94 | Rim drive | 1600 | MBY1000 | 205 |

| φ3.5*13 | 55-60 | 17.09 | ≤25 | 160 | 111.2 | Rim drive | 2000 | JDX1000 MBY1000 |

250 |

| φ3.8*12 (closed-circuit) | 110 | 16.6 | ≤25 | 175 | 123.6 | Central drive | 2500 | JQS2500 | 203 (excluding drive parts) |

| φ3.8*13 | 66 | 16.4 | ≤25 | 195 | 129.3 | Central drive | 2500 | MFYX250 | 286 |

| φ4.0*13 | 80-85 | 15.5 | ≤25 | 235 | 155 | Central drive | 2800 | JS140-A | 220 (excluding drive parts) |

| φ4.2*13 (closed-circuit) | 140-155 | 15.6 | ≤25 | 240 | 157 | Central drive | 3550 | JS150-B/MFX355 | 287 (excluding drive parts) |

| φ4.6*13 (closed-circuit) | 170-180 | 15.7 | ≤25 | 292 | 210 | Central drive | 4500 | MFY450 | 346 (excluding drive parts) |

Since 1998, cement factories from more than 50 countries and markets worldwide have purchased more than 2000 ball mills from CHAENG. Therefore, CHAENG has been praised as the most cost-effective enterprise in China.

E-mail: info@chaeng.co

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China