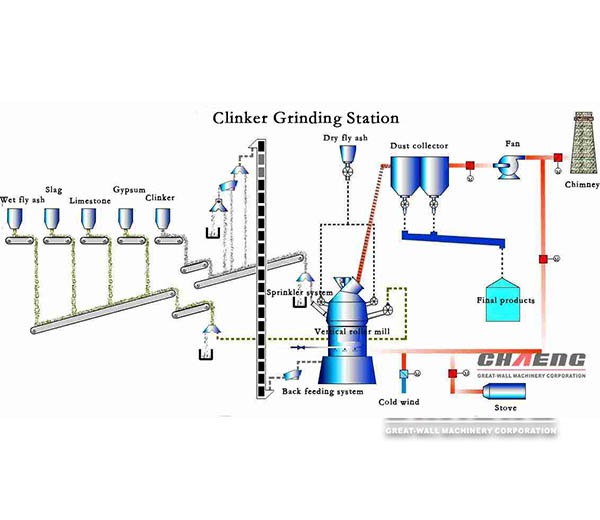

【Product description】: CHAENG clinker grinding station adopts vertical roller mill to grind clinker, improves production efficiency, reduces power consumption and environmentally friendly.

【Product capacity】: 20-380t/h

【Main equipment】: Roller presses + Ball mill/ Vertical roller mill

【Application】:cement plant, clinker grinding plant

1. Simple in technology process, saving capital construction investment.

2. With excellent environmental benefit, low noise, and low dust.

3. Low metal abrasion, slow speed in equipment depletion, stable operation.

4. Production with high degree of homogenization, high degree of fineness, excellent quality, and huge potential marketing.

The electric motor drives the disc through the reducer, and the hot air enters the vertical roller mill from the air inlet. The material falls from the feeding mouth to the center of the disc. Because of the centrifugal force, the material moves from the center of the disc to the edge of the disc. Grinding roller crushed, crushed material continues to move to the edge of the disc until the wind ring at the air flow away, and large particles of material and fell to the disc to continue to crush. The airflow through the upper part of the material separator, the role of the guide vane, the rough material from the cone down to the disc, the fine powder along with the air out of the mill, the dust collector system to be collected powder For vertical roller mill grinding out of the product. The material is dried in contact with the gas in the housing to achieve the desired dry and wet product. By adjusting the angle of the guide fan blades and the rotor speed of the separator, can achieve the required product thickness.

| Items | Scheme I Closed-circuit ball mill system |

Scheme II Combined grinding system |

Scheme III Vertical roller mill finish-grinding system |

|

|---|---|---|---|---|

| Cement types | P·O42.5 | P·O42.5 | P·O42.5 | |

| Cement ratio, % | Clinker | 90 | 90 | 90 |

| Limestone | 5 | 5 | 5 | |

| Plaster | 5 | 5 | 5 | |

| Cement specific surface area, cm²/g | 3500 | 3500 | 3500 | |

| System output, t/h | 170 | 160 | 160 | |

| System power, kWh/t | 41 | 33 | 28 | |

| Annual electricity savings (×10,000 yuan) | — | 400 | 700 | |

| Metal wear, g/t | 50 (Steel ball) | 30 (Steel ball+roller surface) | 5 (Grinding roller+grinding table) | |

| Drying capacity | Weak | Medium | Strong | |

1. EPC project of Yu Hui building materials 900000 T/A cement grinding station

2. Company CAC from Vietnam purchased the ball mill equipment of the cement grinding station

3. Clients from Pakistan – 5000 t/d cement grinding station

E-mail: info@chaeng.co

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China