02 Sep,2020 UTC+8 Views:

After a long-term operation, large rotary kiln and grinding mill always begin to have various problems. Once a rotary kiln accident occurs, it will cause huge loss because of production stoppage. Therefore, the regular maintenance of large rotary kiln and grinding mill, and replacement of the spare parts, can effectively extend the service life of the components.

As a well-known service provider for large kiln and grinding mill, CHAENG can produce large mechanical spare parts (1-150tons/piece) for building materials, cement, metallurgy, mining and other industrial industries, including ball mill trunnion, girth gear, vertical mill roller and table, rotary kiln shell, support roller, etc. CHAENG is the large parts supplier for many famous enterprises such as China National Building Material Group, Shanshui Cement, Lafarge, Taimu, and Wannianqing cement, TaTa.

1. Over-high output increases the wear of kiln mouth shell, and causes the overheat deformation of the kiln shell.

2. The heat flow is too large but the cooling zone is short, and the working environment of the kiln mouth is poor.

3. The cylinder temperature is too high, the thermal expansion is large, while the strength of the high temperature resistant materials is seriously attenuated.

4. The guard bolts at kiln mouth are loosen, so that the refractory materials fall off, and thus the shell is burnt.

5. Improper handling during burning contaminated soil causes severe corrosion of the cylinder shell.

6. The corrosion of sulfur, phosphorus and chlorine on the kiln shell reduces the thickness and strength of the kiln cylinder, also reduces the plasticity of the steel and increases the brittleness of the steel, which may lead to brittle failure of the kiln cylinder.

It can be concluded that it is very necessary to regularly detect the running condition of the components, and timely find problems, to improve the economic benefits of the enterprise, and effectively extend the service life of the equipment!

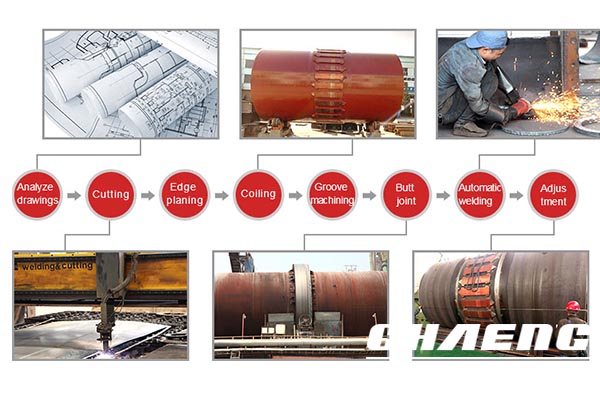

The rotary kiln shell is made of steel plate such as boiler plate and Q235C plate, requiring highly on dimensional accuracy and geometric tolerances.

Due to transportation reasons, the rotary kiln is composed of shell segments. Because the outer circle of the kiln cylinder is not processed, the perpendicularity of the end face to the center of rotation cannot be directly measured. In the process design, the perpendicularity of the end face is converted into parallelism and the coincidence of the axes at both ends according to the structure of the cylinder.

CHAENG adopts local forming method to design specific manufacturing process and welding method of single-segment cylinder according to the detailed requirements of the drawings. After the assembly and welding of the cylinder, perform the post-weld treatment, including non-destructive testing, post-weld heat treatment and pressure resistance test to ensure the high quality of kiln shell.