28 Jul,2016 UTC+8 Views:

Chaeng pulverized coal grinding system specifications can be divided into: GRMC17.21 coal vertical mill, GRMC19.21 coal vertical mill, GRMC24.31 coal vertical mill, its capacity is designed to be divided into: 20t / h, 25t / h, 40t / h. It can meet a variety of applications on the market in the field of coal-fired boilers, and the pulverized coal mill stand is the world's leading, coal preparation facilities have been highly rated domestic and foreign customers.

Firstly, what is coal vertical mill production process ?

Second, what coal vertical mill working principle is it?

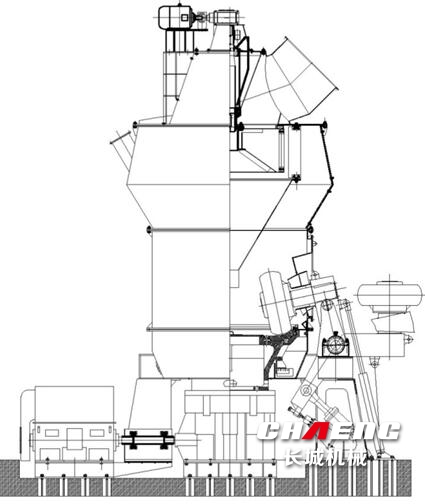

After coal vertical mill feed, with the rotation of the disc from the center to the edge of the movement, at the same time the material is extrusion and grinded by the coal vertical grinding mill roll . After grinding disc be brought up from the hot gases into the air ring at the edge of the pulverized coal , the meal back to the disc and then grinding, qualified powder into the hot air from the bag filter after collecting chute transported by air to the library side of the elevator into the finished products. Drying heat generated from the combustion hot stove in the scene. Hot air through a pipe into the mill, the mill after the gas cleaning system by the fan into the chimney, where a portion of the cycle again into the mill through the circulation duct.

Thirdly, What are the characteristics of coal vertical mill technology advantages?

1, set the grinding, drying, separator, delivery in one energy efficient.

2, disc shape is conducive to the material after grinding the edge of the disc was promptly thrown into the isolated, reducing over-grinding. High efficiency, low power consumption.

3, coal vertical mill roll grinding machine pulls out, the repair and replacement of wearing parts is very convenient.

4, the roller sleeve symmetrical shape of the tire structure, can be used upside down, long life, low operating costs.

5, the separator for the efficient dynamic - static separator, high efficiency, small resistance.

6, with a limit device can be prevented when no material on the disc and roller disc in direct contact, wear and avoid severe vibration.

Chaeng coal vertical mill lead international process design, sophisticated heavy equipment, lean manufacturing and installation, rich experience in project delivery, the fastest speed of delivery, as domestic coal vertical mill production line leading brand! In cooperation with the chaeng, it is choose rest assured that the use of peace of mind, a new service!