27 Jan,2016 UTC+8 Views:

The annual output of 400,000 tons of GGBFS production line, which signed with the Great Wall Machinery.This project is beneficial to ecological environment protection. It not only gains good economic benefit, but also gets good social benefit. Great Wall Machinery is a professional supplier of 400,000 tons of GGBS production line. Provide "turnkey" service from civil engineering to debugging and capacity and standard reaching to customers, let customers put into production of GGBS with saving worry, saving effort and high-efficiency.

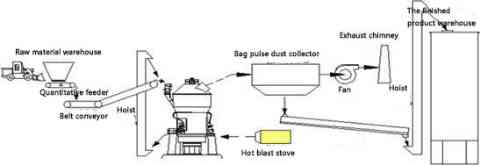

Working principle:

The original slag by grab machine into the feeding bin, measurement by conveyor belt into the spiral feeding device for feeding Vertical Roller Mill, the material with grinding disc to rotate under the action of centrifugal force moving from the center to the edge in grinding process, after compaction, degassing, grinding process, the material is entered from the air ring hot air with, and instant drying, smaller particles were brought to the powder selecting machine for sorting, coarse powder return disc grinding. Qualified fine powder was brought into the bag type dust collector, was finished after the collection of gas powder separation. Finished product collection after delivery into the finished bulk library, exhaust fan exhaust silencing by post. Large granular material part difficult to grind spit slag mouth into the external circulation system through the wind ring, by removing iron, again by the hoist feed mill. Hot air drying and mill needs ventilation is provided by the hot blast furnace, the insufficient part supplemented by cold air valve from the atmosphere.