05 Dec,2015 UTC+8 Views:

1. Introduction of Slag Powder

Great wall is a specialized suppler of slag powder production line. The slag powder is a kind of superfine powder grinded out of the blast furnace slag that is cooled rapidly in the water. Its chemical component includes the SiO2, CaO, MgO, Al2O3, Fe2O3, TiO2, and MnO2 etc. This powder contains 95% and more and amorphous solid and dicalcium silicate, gehlenite, aedelforsite and other minerals. It is structured with the similar component to the cement.

Due to the ultrahigh active property, the slag powder is commonly used as the superior admixture for the cement and the concrete. It is a new kind of eco-friendly building material.

2. Application of Slag Powder

This slag powder is mainly added in the cement and the commercial concrete. Used in different ways, it is commonly perceived as the admixture, addition material and the main mixed material. This powder works actively in improving some features of the cement and concrete, such as workability, early strength, reduction of heat generated in hydration, etc.

3. Technological Features

The slag powder production line utilizes the vertical slag mill that is characterized by advanced technology, reliable production, systematic energy conservation and wide application range at home and abroad. This production system takes various materials as fuel, such as blast furnace gas, coke oven gas, natural gas, water gas, pulverized coal, etc.

Our slag powder production line is cost efficient and space saving. Aside from the short payback time of investment, this product is consistent with the national strategies about energy conservation and environmental protection. It is one of the projects the government encourages people to develop.

4. Characteristics of Vertical Roller Mill

(1) Great wall vertical roller mill in the slag powder production line exerts high grinding efficiency. Based on the principle of squeezing the material to be smashed, the materials are grinded, cut and impacted in the mill. With the help of the air flow in the mill, the finely grinded material will be carried out in time, avoiding the excessive grinder. In general, the material stays in the mill only for 2 to 4 minutes. This machine performs with 165% grinding efficiency of the ball mill, decrease 30% of power consumption.

(2) Great wall vertical roller mill is also efficient in drying the material, with hot air jetted at high speed from its annulus seam. Owning to the wide ventilation cross section and low resistance, this vertical mill is able to dry the material with 8% moisture via the exhaust gas from the preheater in the end of the rotary kiln. If the slag powder production line uses the air heater, the material containing 15% to 20% moisture can be dried effectively.

(3) The large granular materials are allowed to enter the roller mill. In general, the particle size of the material is about 5% of the diameter of the grinding roller. The large granularity of the materials for milling reaches 150 to 200mm. This equipment owns preeminent processing performance, excellent standalone productivity and high operating rate. Moreover, it has lower abrasion of metal parts than the ball mill.

(4) Due to the high adaptability to the grinding materials, this vertical mill of our slag powder production line is available in grinding various crude fuels including the limestone, sandstone (SiO2>90%), cement clinker, coal and blast furnace slag etc. Regardless of whether the materials are easy to be grinded or get the mill abraded, this machine is capable of making the qualified product with distinct fineness and specific surface areas, with its adjustable inner structure and rational operation.

(5) Slag powder production line shows simplified process and compact layout, so does the vertical mill. Moreover, this machine can be located outdoors and its daily maintenance cost is very low. It only needs 70% infrastructure investment of the ball mill.

(6) This vertical roller mill features optimal integrated tightness, small amount of dust, low noise. It offers comfortable environment for workers.

(7) It supports efficient control on the finished product and flexible adjustment on products. Meanwhile, the intelligent and automated operation is easily applied on the vertical mill machine.

(8) The vertical roller mill is not suitable for the materials with high hardness and abrasive resistance; it adopts the more expensive wearing parts than the ball mill.

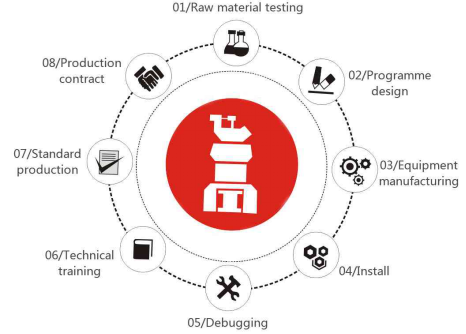

5. Slag powder production line service

In order to ensure customers projects are carried out and completed successfully, Great Wall Machinery has brought out the "eight services" and provides the guidance during the total project, from early start to final products

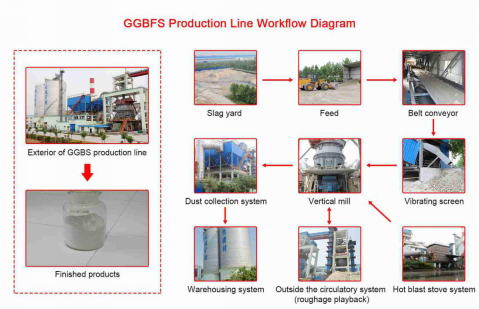

6. Slag powder production line process

7. Working Principle of slag vertical roller mill

The material through the feed tube fell into the center of grinding plate, and then the materials outwards the surrounding area of grinding plate at centrifugal force, to forms a certain thick layer of materials bed, at the same time material was crushed by number of vertical mill rollers. The materials continuous moving to the outer edge of the grinding plate, off the grinding plate materials rising with the hot air which enter from wind ring into the vertical roller mill, through the vertical roller mill shell into the middle of the separator, in this course materials and hot gas got a fully heat exchange, the water quickly evaporates. Separator controls the finished product output size, greater than the specified size are separated and fall back to the plate, while meet the fineness demands are brought through the separator into the finished product warehouse.