14 Mar,2019 UTC+8 Views:

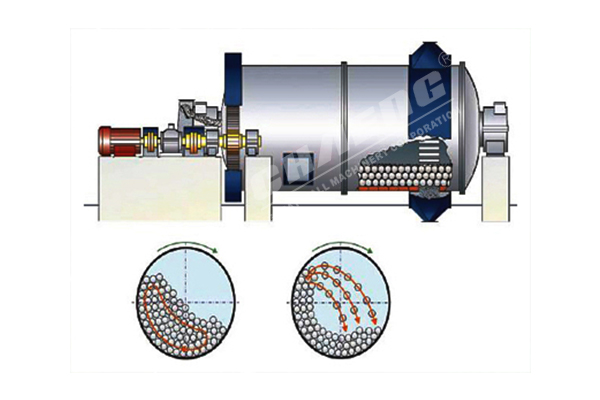

Correct use of steel grinding balls of ball mill: The newly installed ball mill has a running-in process. During the running-in process, the ball volume is added for the first time, accounting for 80% of the larger ball load of the ball mill. The proportion of the ball added can be added in the size of the steel ball size of 120 mm, 100 mm, 80 mm, 60 mm, 40 mm. Different ball mill models have different ball loadings. For example, the 3000 ball mill has a larger ball load of 9.5-10 tons. The first addition of steel balls (120mm and 100mm) accounted for 30% to 40%, the medium ball 80mm accounted for 40% to 30%, and the small balls (60 and 40mm) accounted for 30%.

Why are the ball mill grinding balls volume only 80% added during the ball mill running-in process? After the ball mill is installed, the ball mill size gear needs to be meshed, and the processing capacity should be gradually increased. After the ball mill is running normally for two or three days, check the meshing of the large and small gears. Wait until everything is normal, open the ball mill into the hole cover and add the remaining 20% steel balls for the second time.