12 Aug,2016 UTC+8 Views:

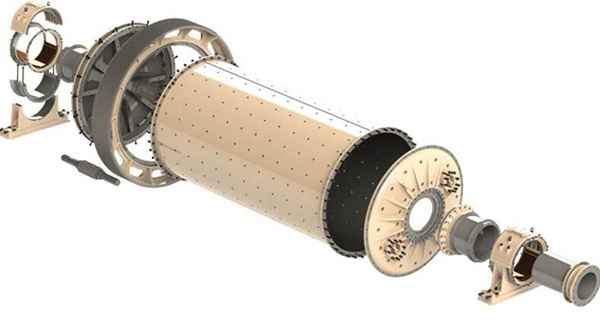

Stone ball mill mainly composed of feeding unit, feed unit, cylinder unit, discharging part, bearing unit, drive unit, coupling, slow drive unit, electrical unit, the motor, . It is worth mentioning that the chaeng ball mill supporting all steel parts, such as the ring gear, hollow shaft, cylinder, support equipment, etc., by the chaeng foundry processing production, and better quality.

1, the feed unit and a discharge unit: the discharge port to prevent air leakage, air lock device should be installed, and then with the delivery device is connected, otherwise it will affect the mill discharge.

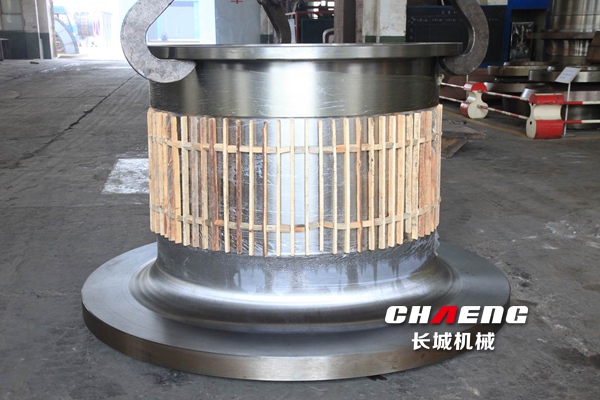

3, hollow shaft

4, the barrel portion: This section is also called turning part, by access to materials spiral tube, out of the compound by the air shaft, gear, cylinder, liner and overflow type diaphragm plate, overflow type grate plate, lead material, member material ball separation systems and lifting devices, blind boards composed.

Interior of the cylinder is provided with a double diaphragms and modular screen partition plate, the cylinder is divided into three positions, three positions equipped with activated liner, fine comb joints discharge grate plate. Combined with the double diaphragm plate screen partition plates front and rear positions may need to be adjusted according to production, each grinding compartment removable grinding of different sizes, in three positions of the rear end is provided with a small hole discharge grate plate, its purpose is to prevent the grinding mill. After the discharge grate plate is provided with lifting plate, put it into the material in a timely manner into the hollow shaft of the feed screw within the barrel in order to promptly discharged.

Repair or replacement of the mill grinding and handling parts, each bin are set up manhole, three positions with a double hole (can also be used as four positions)

5. The support portion.

The entire turning part relies on two hollow shaft supported on two main bearings. Out of the compound by the air shaft coupling bolts and barrel flat cap.