30 Jan,2018 UTC+8 Views:

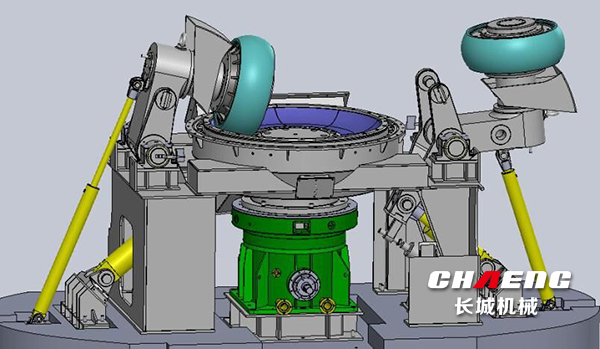

Vertical mill is also known as roller mill, it is widely used in large-scale material grinding and ultra-fine grinding processing in coal, cement chemical, electric power and other industries, it is a set of crushing, grinding, drying, grading, One of the ideal milling equipment industry, for the preparation of pulverized coal products can meet the fineness of the industry and national standards.

In the fly ash production process, investors pay the most attention to environmental assessment. Environmental protection can become the first manufacturers to consider the issue.

Chaeng fly ash vertical mill technology introduction:

1, the raw fly ash from the yard of coal through the grid sieve after falling onto the belt conveyor, the iron by the electromagnetic separator, the belt conveyor to the raw coal storage for storage.

2. After the pulverizing system has been started, open the rod valve at the bottom of the original coal bunker, start the sealing measuring tape to the fly ash vertical mill, and the fly ash enters the fly ash vertical mill for drying and grinding.

3, hot air from the hot blast furnace or cement production line emissions, the system fans under the suction, into the fly ash mill, with the grinding mill was full of fly ash for heat exchange, with pulverized coal at the separator Sorting, the fineness of unqualified coarse pulverized coal fell onto the grinding wheel again, qualified pulverized coal flow into the explosion-proof air box pulsed dust collector is collected, after the round of unloading into the pulverized coal warehouse.

4, raw materials in the debris, such as part of fly ash , metal blocks, etc., through the wind ring, spit slag mouth out of the mill.

Chaeng fly ash environmental performance:

1. fly ash fully enclosed internal production, to ensure that the production of coal in the process does not spill, resulting in dust pollution.

2. chaeng mechanical self-made stacking yard closed heap, to prevent the coal from the source to cause pollution.

3. Equipment installation convergence dust collector, receiving conveyor belt and part of the dust spill.

4. Vertical mill equipment to achieve energy-saving production, can reduce energy consumption and reduce costs.